Not known Details About Premier Aluminum Llc

Not known Details About Premier Aluminum Llc

Blog Article

Indicators on Premier Aluminum Llc You Should Know

Table of ContentsThe smart Trick of Premier Aluminum Llc That Nobody is Talking AboutThe Best Strategy To Use For Premier Aluminum LlcThe 5-Minute Rule for Premier Aluminum LlcThe Premier Aluminum Llc Statements

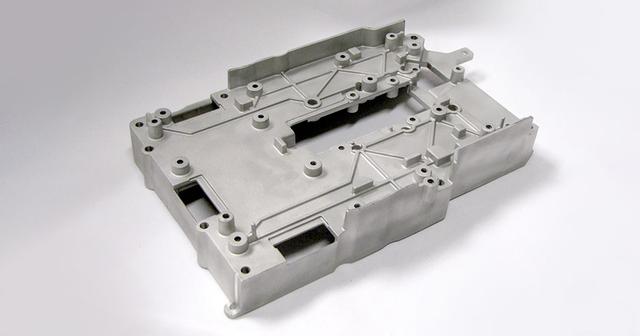

(https://soundcloud.com/premieraluminum11)Typically, a buyer's key duty was to find competent and receptive distributors. Sometimes, buyers presumed that any type of provider happy to contractually satisfy the purchase need was certified. Utilizing low expense and unqualified distributors can trigger quality concerns, and lost time and money in the long run. To assist you through the process, here are some points to take into consideration when picking the right metal spreading distributor.

For instance, a business that only utilizes the investment casting process will try to sell you on why that process is best for your application. But what if using the sand casting procedure is best for you and your demands? Instead, try to find a provider that uses a range of casting processes so the very best alternative for YOU is selected

If collaborating with a solitary resource for all of your spreading needs is very important to you, the vendor needs to be varied in its capacities. When combined with other incorporated abilities, this can assist simplify and compress the supply base. When picking the ideal casting distributor, cautious factor to consider needs to be offered to quality, service, and cost.

Some Of Premier Aluminum Llc

Purchasers increasingly pick casting providers that have machining capacities. This can avoid conflict if problems are uncovered during machining. If a 3rd party is machining, it may result in "finger-pointing" about who is at fault. Is it a casting concern or a machining problem? If the spreading provider uncovers a problem throughout machining, the problem is settled much faster without any disagreement over whose mistake it is.

What do you need from your casting vendor? Are you looking for somebody to just supply a steel element to your front door or do you need more?

Some shops are minimal or specialized. Make sure the vendor can satisfy all your product or alloy demands to eliminate the demand for multiple distributors.

The 5-Second Trick For Premier Aluminum Llc

Study the vendor's web site. Speak to a sales rep or service associate. Ask a great deal of concerns. Visit their facility. Get an understanding of what they can do for you and if you can see on your own developing a solid, mutual connection with them.

Aluminum is also lightweight and has excellent corrosion resistance, making it excellent for applications where weight and longevity are very important factors. In addition, light weight aluminum casting is a cost-effective approach of manufacturing, as it requires much less power and resources than various other methods. Iron casting, on the other hand, includes pouring liquified iron right into a mold and mildew to create a wanted form.

Things about Premier Aluminum Llc

Iron spreading is additionally able to stand up to high temperatures, making it ideal for use in applications such as engine components and commercial machinery. Iron spreading can be more costly than aluminum spreading due to the higher price of raw materials and the power called for to melt the iron. When making a decision between light weight aluminum spreading and iron spreading, it is necessary to take into consideration the details requirements of the application.

In conclusion, both light weight aluminum casting and iron spreading have their very own one-of-a-kind advantages and disadvantages. There are 3 sub-processes that fall under the classification of die casting: gravity die spreading (or long-term mold and mildew spreading), low-pressure die casting and high-pressure die spreading. To obtain to the completed product, there are 3 key alloys used as die casting product to pick from: zinc, light weight aluminum and magnesium. Report this page